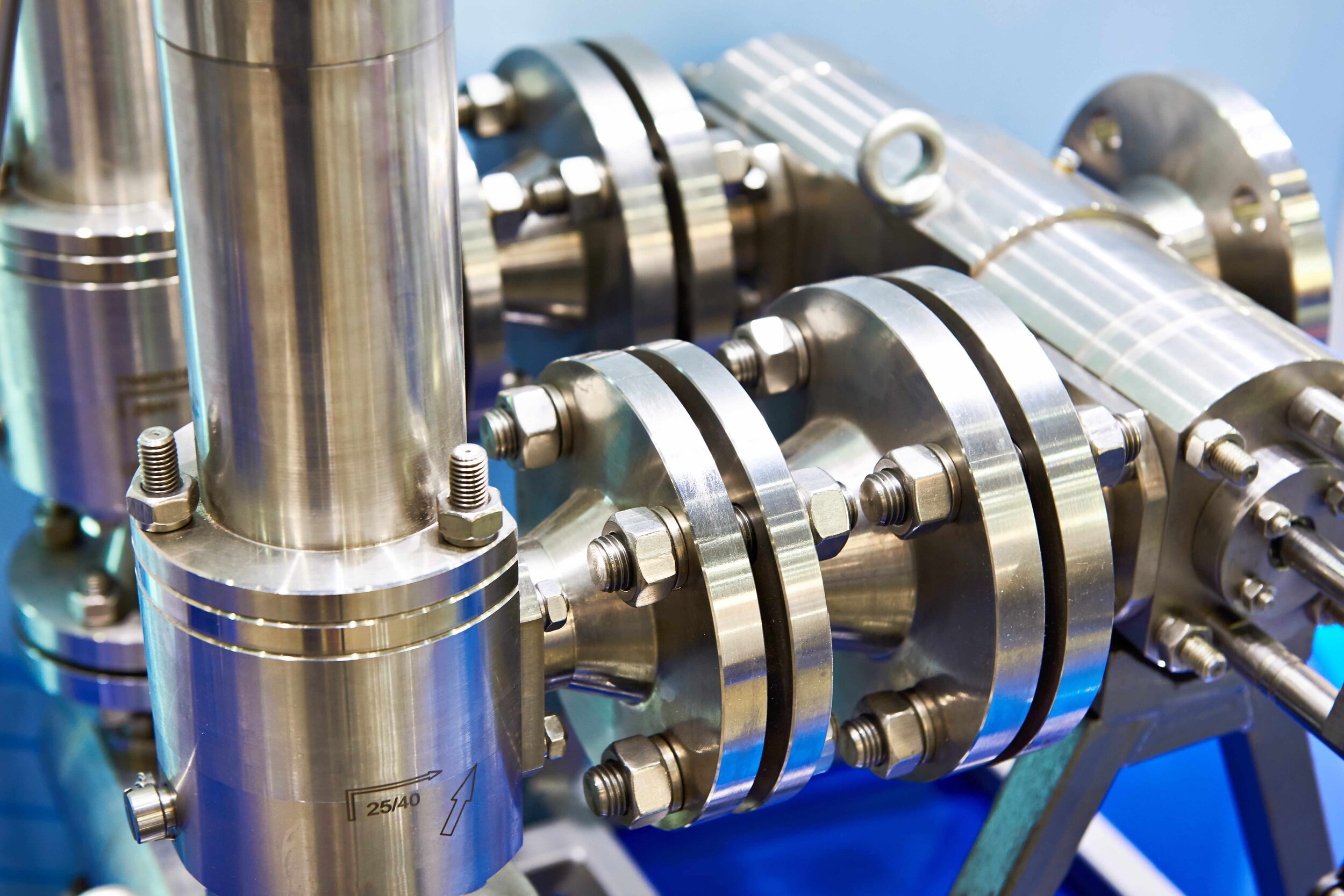

Precision Machining Services

in Conroe, TX

When nothing less than exact will do, choose Conroe Machine. Our precision machining services deliver tight-tolerance, premium-quality products no matter how complex the design. With the capacity to handle everything from unique, one-off orders to production quantities and the expertise to assist in research and development, we are a one-stop machine shop for all your metalworking needs.

Extensive Materials and Specifications Capabilities

Specifications and Capabilities

5-axis machining

Up to 25.9" turning diameter; Up to 101.7” turning length;

240 degree B-axis travel; 11.8” Y-axis travel

Milling

Up to 120”x60”x38”

27” 4th axis

Lathe Work

Up to 32” outside diameter x 126” long

Gun Drilling

From 0.093’’ to 6.000’’ interior diameter

Lengths up to 120’’

Materials We Work With

Conroe Machine has capabilities to cut a variety of materials. We have listed several below but this is not an all-inclusive list. Please contact Conroe Machine for any questions on materials not listed.

| Alloy Steel | 4140, 4142, 4130, 4330 V Mod, 4340, 6150, 8620 |

|---|---|

| Aluminum Alloys | 2011, 2024, 6061, 7075 |

| Carbon Steel | 1018, 1020, 1026, 1045, 1144, 1117, 12L14, 1215 |

| Copper Alloys | 360 Brass, 464 Naval Brass, Manganese Bronze, Aluminum Bronze, Nickel Aluminum Bronze, Phosphor Bronze, Beryllium Copper, Copper |

| Nickel Alloys and Super Alloys | Hastelloy C-22, Hastelloy C-276, Inconel 625, 718, 925, Monel 400, Monel K-500, Stellite, MP35N |

| Plastics | Delrin, Kynar, Peek, Phenolic, Nylatron, Rulon, Teflon, Polyethylene |

| Stainless Steels | 303, 304, 316, 410, 416, 420, 440C, 13-8, 17-4, 18-8, A286 (660), 2205 Duplex, Nitronic 50, Nitronic 60, ASTM A193, Grade B8M, P550 Non-Mag |

| Tool Steels | A2, H13, M5, S7 |

Our Services

Precision Machining

CNC Lathe/Turning (Small & Large Spindle)

4 Axis Milling

5 Axis Mill Turn

High Volume Robot Cells

Thread Cold Rolling

Gun Drilling

EDM

Saw Cutting

Cold Rolling

Honing

Deburring

Boring

Gun Drilling

On center holes

Eccentric (off center) holes

Tight position tolerances/hole size

High precision drift control

Our Process

Our operations are based on two principles: doing your job quickly and doing it right, turnkey and end-to-end. We lean on our expertise to stay flexible and develop the best course of action for each project that stays within those guiding parameters.

Our Equipment

40+ Precision Machines

| Resource Capabilities | Resource Type |

|---|---|

| Travel: 24.8" x 11.8" x 101.7" Max Turning Dia: 25.9" |

Multitasking Turning Center |

| 05." to 10" OD | Small CNC Lathes |

| 4" to 20" OD 126" Long |

Medium CNC Lathes |

| 8" to 32" OD 126" Long |

Large CNC Lathes CNC Horizontal Turning Centers |

| 3" to 30" OD 250" long |

Weiler Lathes: CNC Turning Centers, CNC Lathes |

| 3" to 10" OD 2.5" long |

Robot Cells |

| 60" x 36" x 35" (LWH) 14" Dia. in 4th Axis |

Small Mills |

| 120" x 48" x 40" (LWH) 25" Dia. in 4th Axis |

CNC Vertical Machining Centers |

| 0.750’’ to 6.000’’ ID Lengths up to 120’’ |

BTA Machine |

| 0.093'' to 0.750’’ ID Lengths up to 120’’ |

Eccentric Gun Drills |

Certified and Equipped for Premium Quality

At Conroe Machine, we stand behind the work we do because we’ve integrated quality control and assurance into every aspect of our operations. From outgoing, incoming, and first article inspections on all parts, to regular tool calibration, to the use of data recording software throughout the manufacturing process, our quality management practices ensure superior final products every time.

Our quality control equipment includes:

Faro Arm for accurate point measuring

Hardness tester for nondestructive hardness testing

Zeiss CMM for highly precise QA measurement

We are proud to be API certified and ISO 9001 certified by independent certifying company DNV.

Serving a Wide Variety of Industries

-

Oil & Gas

Our Texas roots have made us seasoned producers of downhole machined assets. We are proud to be API Spec 7-1 certified.

-

Aerospace & Aviation

Our aerospace and aviation customers rely on Conroe Machine for the most exacting standards, flexible partnership, and fast turnaround.

-

Flow Control (Valves)

Conroe Machine is the perfect choice for machining your flow control valves, flanges, and pump housings, whatever your industry.

Why Conroe Machine?

You won’t find a machine shop with a better combination of capacity, knowledge, and customer service than Conroe Machine. In our more than 20 years in business, we’ve built our business by providing bend-over-backwards service, with honest and transparent lead time estimates.

Thanks to our large facility and extensive experience collaborating with engineers, we’re able to take on specialized jobs, assist your R&D, machine one-off pieces, and more. We also offer round-the-clock service and delivery for customers across the U.S.